Quality control process

Inspection equipment

Quality reports & services

Rework & Refund policy

Quality Control Process

Learn the most stringent inspection methods we applies over the course of the entire manufacturing process.

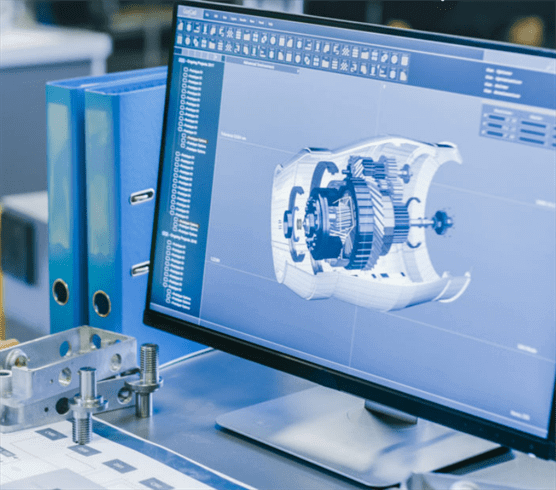

Pre-production

Technical assessment

Before the production stage begins, our engineering team performs a technical assessment on your parts design. This includes an assessment on important factors such as material, surface finish, structure, process, and other details of your 3D and 2D drawings.

Material verification

On our customer’s request, we provide a certification of the material we used for making your parts. The report comes from the raw material manufacturer and usually includes: material heat number, material grade, material dimensions, mechanical properties, chemical analysis, etc.

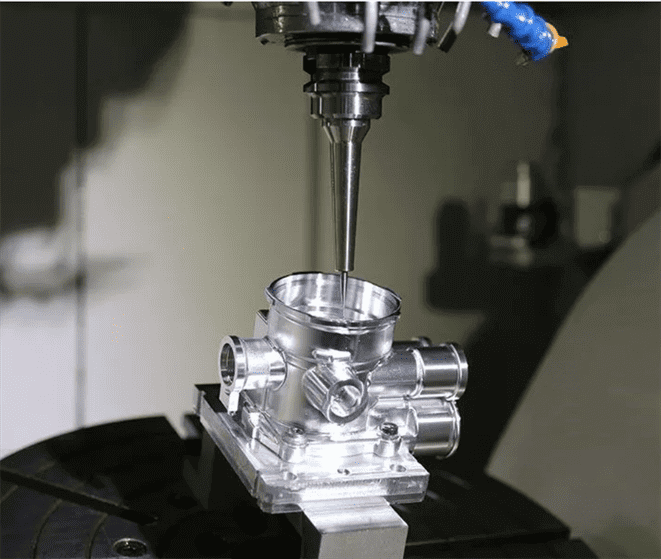

In production

On-site inspection system

In precision machining, it is important that materials being worked on is always at the right position. With on-site inspection system, positions are examined automatically, and adjustments are made accordingly. Using on-site inspection system further helps avoid issues at the early stage, saving cost and time.

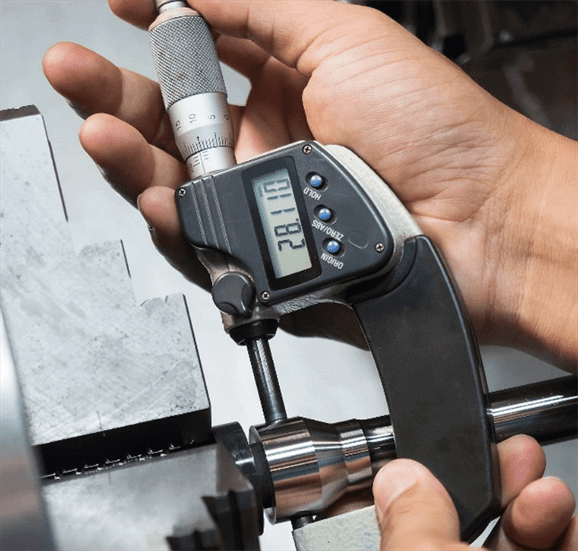

In-process quality control

At Promise Technology, to ensure quality at high level, the quality control staff conducts routine inspections for all parts that are being produced every 2 hours. This further prevents risks from happening.

Before delivery inspection

Full-dimensional inspection report

For all orders, we provide inspection report on request. This report will include the following: quantity of parts, critical dimensions, threads and tolerances, thicknesses and depths, part appearance, etc.

Packaging

Ensuring that the parts we manufacture are of the highest quality is important. We know about the unpredictability of logistics. Therefore, we make sure we lower the risk to the parts during our packaging process. Four layers of protection: 1. wrapping paper 2. EPE 3. foam 4. paper/wooden box are applied during the packaging process, ensuring that we deliver the most high-quality and beautiful parts to you.

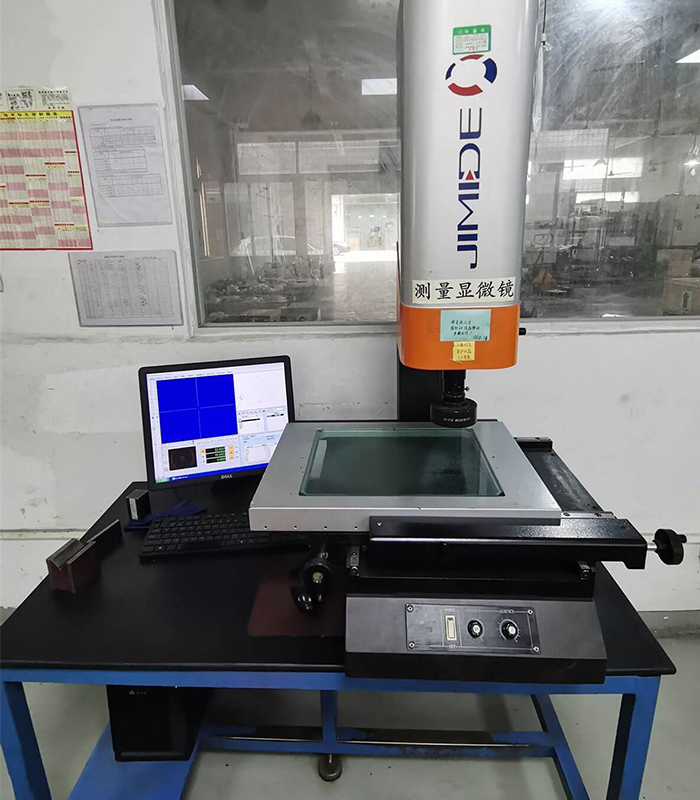

In-house inspection equipment

CMM

Profile Projector

High Gauge

Resolving Quality Issues

At Promise Technology, it is our aim to deliver high quality parts that matches your requirements and expectations. However, if your order fails to meet your specifications, you will be covered with our Rework and Refund Policy. Kindly get in touch with us within five business days of receiving your order, and we will resolve the problem rapidly within 1-3 business days.

Conditions for Rework

- Unacceptable processing defects

- Fail to meet tolerance requirement

- Incorrect material / finish

Conditions for Refund

- The part is not machinable

- The customer does not agree to rework

- Other reasons