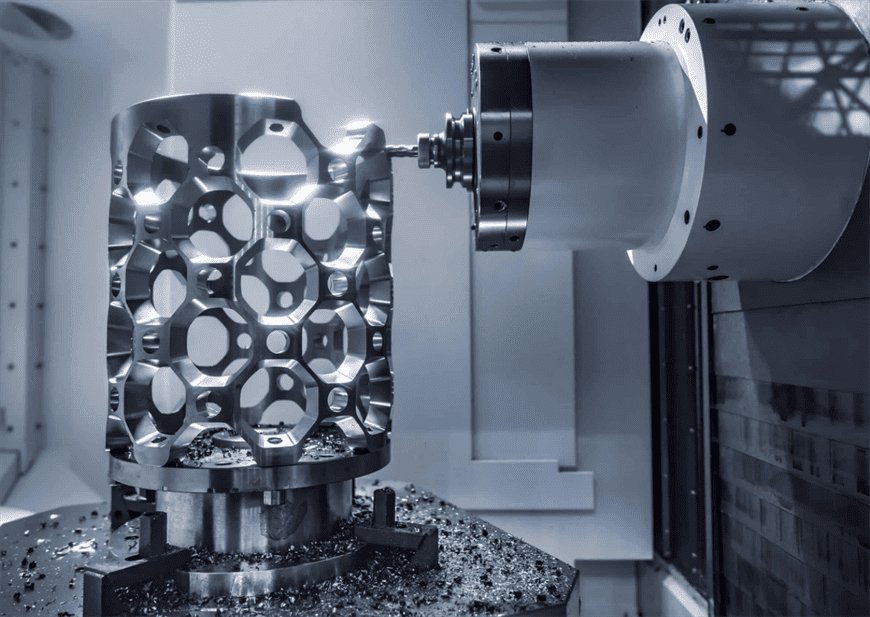

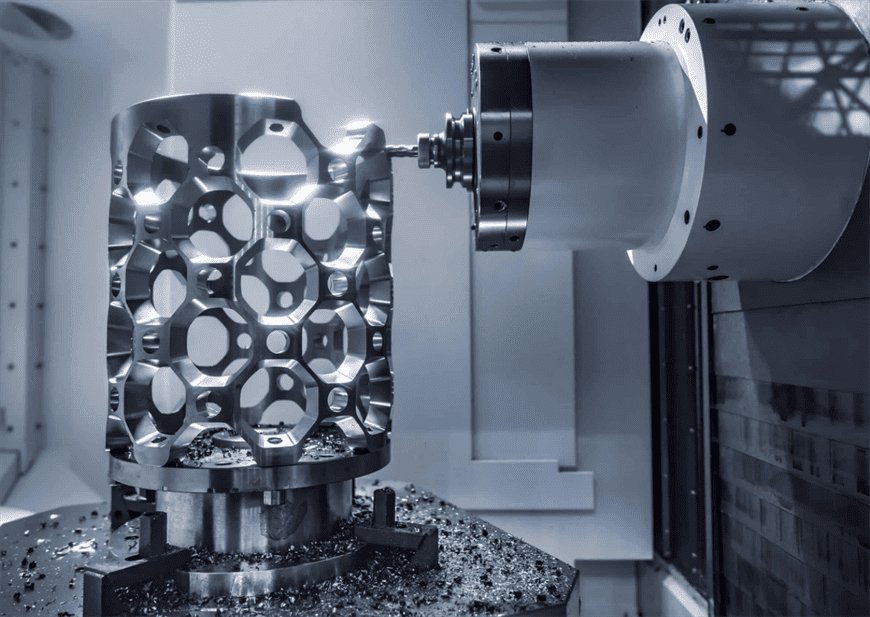

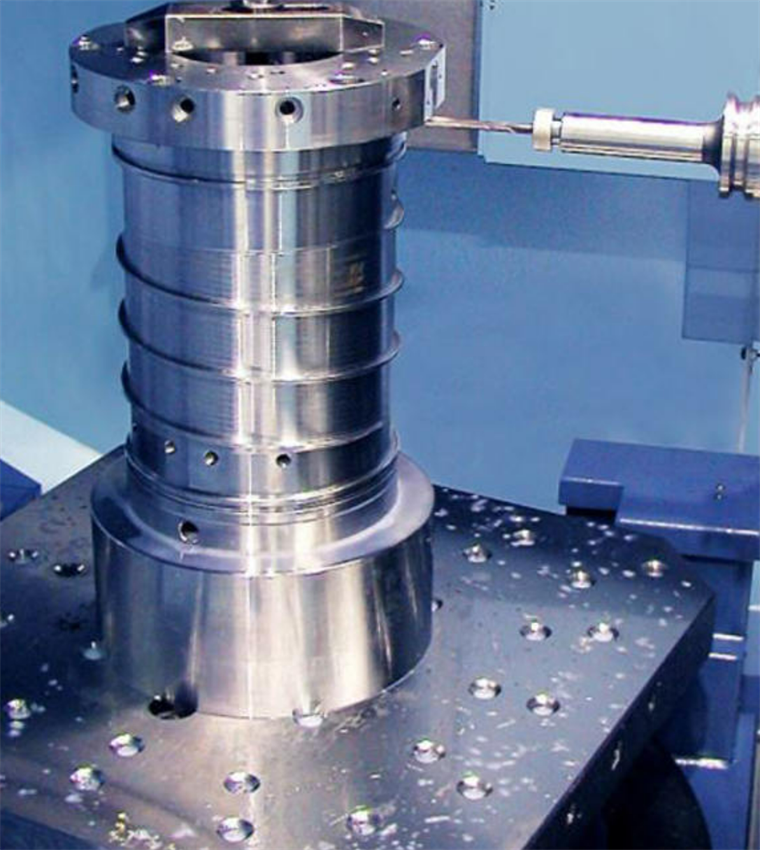

CNC Machining Services China

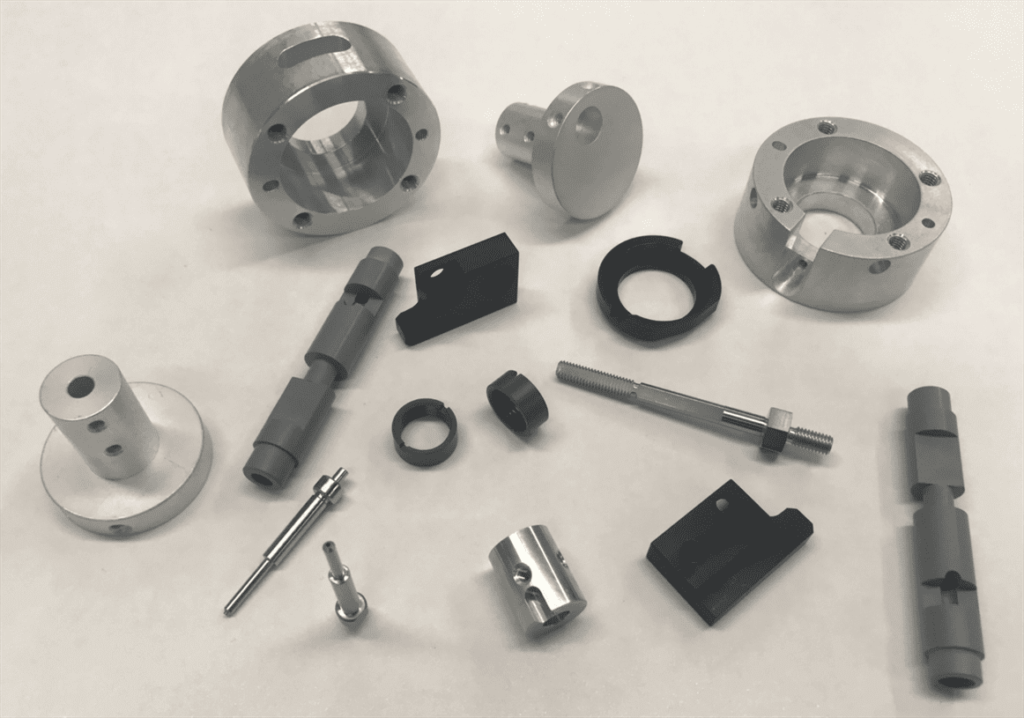

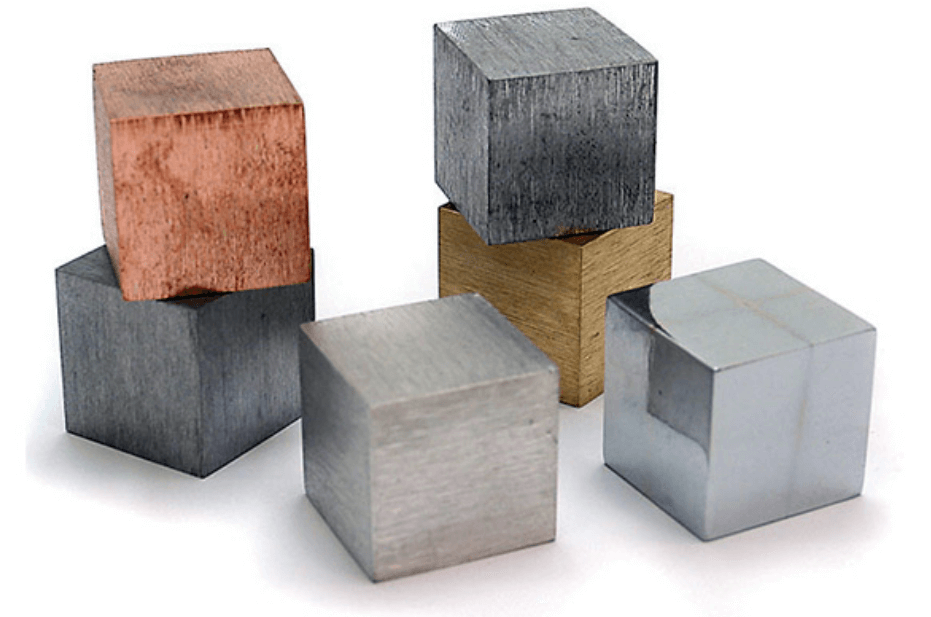

Leading computer numerical control(CNC) machined parts delivered to your door in days. A wide variety of CNC materials and secondary finishes available from our manufacturing partners.

Could you be looking for a CNC machining service factory?

Well, then this marks the end of your search. You came to the right place. We are here to meet your exact CNC machining services needs by offering you professional, quality, and cost-effective services. From small to large CNC machining services, our team is always on their heels to meet each client’s design specification and ensure that what they offer will leave the customer satisfied.

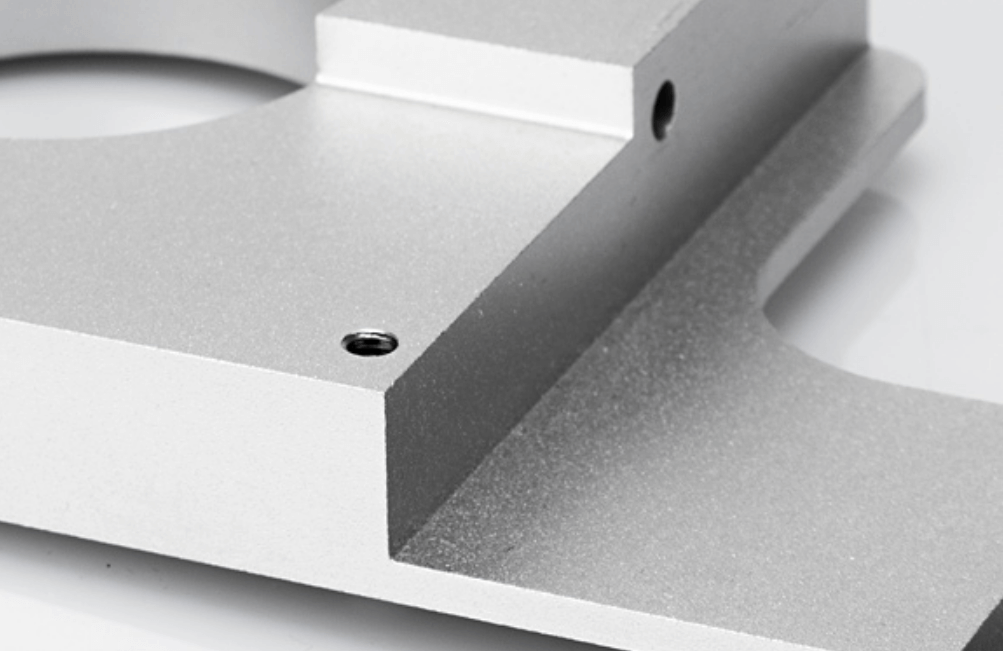

As-machined: As-machined parts have the tightest tolerances, as no extra operations are performed on them. Marks following the path of the cutting tool are visible though.

Bead Blasted: Adds a uniform matte or satin surface finish on a machined part, removing all tool marks. Bead blasting is mainly used for aesthetic purposes, as the resulting surface roughness is not guaranteed. Critical surfaces or features (like holes) can be masked to avoid any dimensional change.

Anodized: Anodizing adds a thin, hard, non-conductive ceramic coating on the surface of aluminum parts, increasing their corrosion and wear resistance.

Powder Coating: Powder coating adds a thin layer of protective polymer on the surface of the part. Powder coating is a strong, wear-resistant finish that is compatible with all metal materials and can be combined with a bead blasting to create parts with smooth and uniform surfaces and excellent corrosion resistance.

To Promise Technology, we work on the principle that quality comes during the process of manufacturing, not after the fact. We use advanced production technologies and strict control systems to ensure high quality. More importantly, the quality-oriented attitude has been so entrenched in the mind of every single employee.

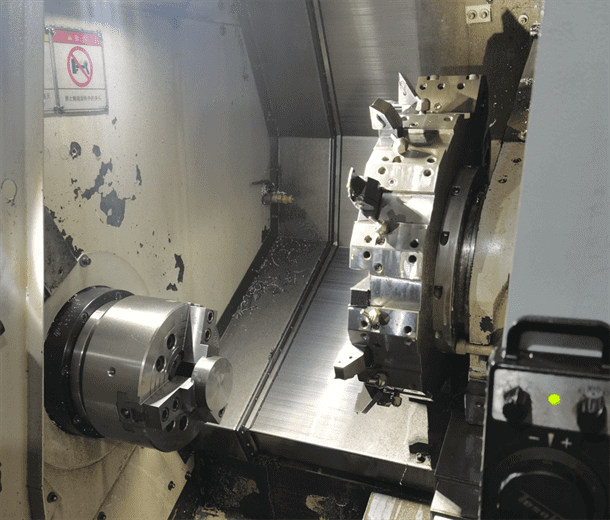

Our use of powerful automation makes the machining of your custom parts easy by eliminating slow and antiquated processes that also lead to reduce development cycles and increase delivery speed.

In China, the competition between suppliers keeps the prices fair. Our fully optimized equipment helps us maintain a low price without sacrificing the quality and performance of your parts.

Promise Technology advanced machining technologies mean we can offer hundreds of processes and materials to our customers. Promise Technology relies on machine learning algorithms to calculate the overall cost of your parts.

Our advanced CNC machines help us achieve the ideal time of seconds to move from one operation to another. Our machines feature many pre-fitted tools that lead to rapid tool changes.

We offer instant quotes based on a CAD file without complicating the processes through long email chains. We calculate prices based on millions of orders we've previously processed.

For your time-sensitive machining projects, Promise Technology offers economic lead-time options.